BSB A60 Multiblade Marine Fire Damper

£POA (Please contact us for latest price)

For use in marine applications to protect the integrity of fire rated bulkheads and decks. Each A60 damper is controlled by an electrical failsafe spring return actuator combined with a thermoelectric tripping device (thermal fuse) and volt free contacts for remote status indication.

The A60 Marine Fire Damper has been tested in accordance with EN1751 with case leakage conforming to classes A, B and C and closed blade leakage to class B.

Call us now for expert technical advice on 01202 600011 or use our live chat functionality.

The BSB A60 multiblade Marine Fire Damper is designed for use on marine vessels to protect the integrity of fire rated bulkheads and decks. Each A60 damper is controlled by an electrical failsafe spring return actuator combined with a thermoelectric tripping device (thermal fuse) and volt free contacts for remote status indication. The A60 damper can be used where the maximum system pressure is 2000 Pa and duct velocities do not exceed 20 m/s. The A60 Marine Fire Damper has been tested in accordance with EN1751 with case leakage conforming to classes A, B and C and closed blade leakage to class B.

Suitable for both vertical and horizontal applications, with airflow in either direction. MED certified for A60 fire performance. Conforms to the current Commission Implementing Regulation.

Options & Sizing

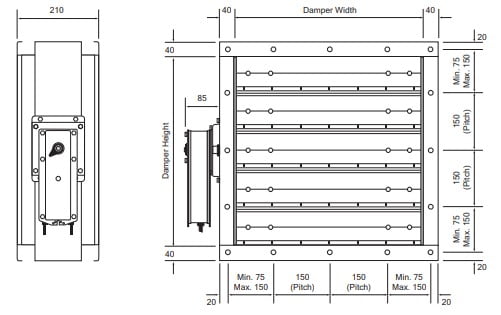

Available in square/rectangular and circular dimensions:

Type A60-S Square/rectangular flange duct connections

- 100 mm W x 100mm H minimum

- 1000 mm W x 1000mm H maximum

Larger sizes are available as Multiple Assembles for vertical installation only to a maximum size of 2080mm W x 1000mm H.

Available in 1mm increments.

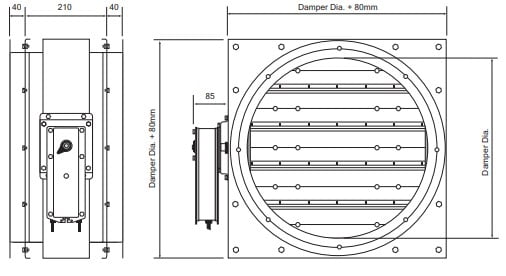

Type A60-C Circular flange duct connections

- 100mm diameter minimum. 1000mm diameter maximum

Available in 1mm increments.

Fire Testing

The BSB A-60 Marine Fire Damper has been subject to comprehensive fire testing for single and multiple sections. The dampers were installed into a steel deck and bulkhead as specified in IMO Res.MSC.307(88)-2010 FTP Code, as amended.

Tested and certificated for 60 minutes.

Testing, Approvals and Conformities:

- Marine Equipment Directive Certified Fire Performance – 2014/90/EU(MED)

- Merchant Shipping Certified Fire performance – SI 2016 No.1025

- UK Module B Certification (MER)

- EC Module B Certification (MER)

- UK Module D Certification of Conformity

- EC Module D Certification of Conformity

- USCG (United States Coast Guard)

- Certificate of Fire Approval

- Lloyds Register Approval to IMO Fire Test Procedures Code, Annex 1, Part 3, for Class AO, A15, A30 and A60 Division bulkheads and decks. In compliance with the appropriate Lloyds Register Rules and Regulations and with the international Convention for the Safety Of Life At Sea (SOLAS)

- Corrosion Tested to BSEN 60068-2-52

- Vibration Tested to BS EN 60068-2-6

- BRE Global Compliant to ISO 9001

Maintenance

A60 Series dampers are designed for normal dry filtered air systems. A programme of planned inspections should be carried out to include full operational checks, correct interface with, and function of, any control systems, cleaning and light lubrication.

As a guide, this should take place on a maximum of six months intervals.

Reference should be made to BS 9999 for more information. Records of damper installation, location and maintenance log shall be kept on board the vessel. These inspection and maintenance programmes may need to be repeated more regularly if the dampers are exposed to inclement/dusty conditions or fresh air intakes. The frequency of such checks should be developed based on site experience.

Call us now for expert technical advice on 01202 600011 or use our live chat functionality.

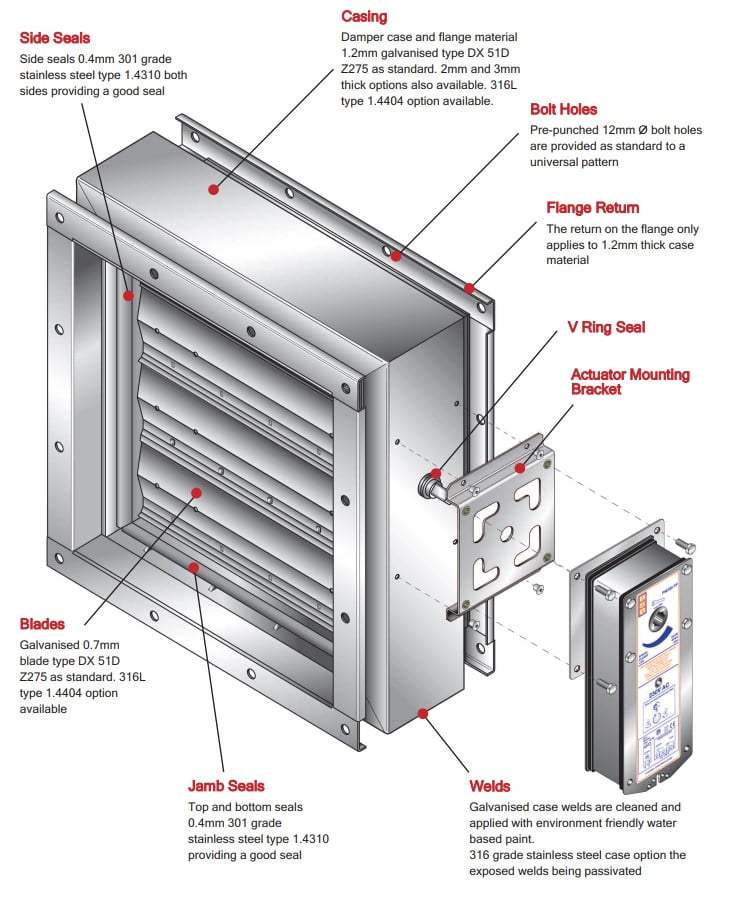

Casing Specification & Options

- 1.2mm, 2mm or 3mm steel flanged design case to BS EN 10346

- Available in galvanised steel and 316 grade stainless steel (steel type 1.4404)

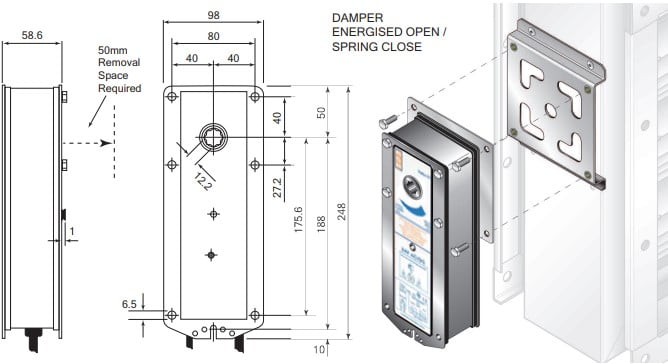

- Single penetration to accept coupling to the direct drive actuator

- Fully seam welded corners provide a rigid and airtight construction

- Exposed welds are treated with protective corrosion resistant, environmentally friendly water based paint for galvanised cases and passivated on stainless steel cases.

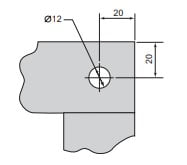

- Pre-punched bolt holes are provided as standard to a universal pattern. Client’s project specific hole pitch/pattern available on request.

Blade Specification & Options

- Supplied with opposed blade operation

- Double skin airfoil in shape

- Blades at 100mm pitches

- Constructed from 0.7mm steel

- Available in galvanised steel to BS EN 10346 (steel type DX 51D Z275) and 316L grade stainless steel to BS EN 10088-2 (steel type 1.4404 0)

- Blades have interlocking engagement to provide low leakage and optimum fire resistance when closed

Gasket Specification

stainless steel peripheral gasketing 0.4mm 301 grade type 1.4310 fitted to both sides, top and bottom of damper internal case.

Linkage Specification

The blade spindles are linked using a gear system, link arms and drive bars to give the opposed blade action. The link arms, drive strips and gears are made from 2.5mm galvanised steel type DX 51D Z275 and is fully enclosed outside the airstream.

Flanges Specification

Pre-punched flange holes are provided as standard to a universal hole pattern. Bespoke configurations are available on request.

Other Components

All other components are manufactured from galvanised/zinc plated mild steel, with 316 stainless options available.

Blade shafts and bearings

The blades are each mounted on two 19mm diameter spindles.

- Available in 1.2mm, 2mm or 3mm thickness galvanised blades and casings

- Rectangular/Square or Circular options

- Rectangular (including actuator)

- Height Options – 100mm, 200mm, 300mm, 400mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm

- Width Options – 100mm, 200mm, 300mm, 400mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm

- Circular (including actuator)

- Diameter Options – 100mm, 200mm, 300mm, 400mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm

See product brochure in documents for full specifciation including weights.

BSB A60 Fire Damper Intro Video